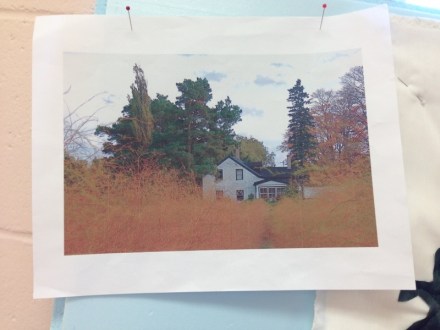

OK, I started “the piece” yesterday – cut the batting and stabelizer to size, prepared a piece of fabric for the sky, started to create a tall evergreen using free motion stitching on hooped organza.

I finished the tree this morning – Laurie in the meantime trying to push me to “get the batting covered.” By that, she meant start placing the fabric for the sky, put in fabric for the trees, lay out the pieces for the asparagus field… I traced the shapes for the main spaces, used the tracings as templates for cutting the fabric.

Next step – I stitched these elements in place, then filled each element with some widely spaced free motion work. ( The asparagus field in the foreground can’t be positioned and stitched in place until everything behind it is in place – the house, trees, shrubs…)

I next started on the house – the focal feature of the piece. More difficult than it first appears because I was using some raw silk for the building – it frays terribly so I had to back it with “steam a seam” (a paper backed iron-on glue) to stabilize it. Whereas the house made yesterday was constructed by cutting out windows and using fabric behind the openings, this building will have to be done with appliquéd windows and doors, each small feature created separately. I was able to construct the main elements of the house this afternoon – the details will come tomorrow.

The right hand side of the piece needs to be filled with leafless deciduous trees – I still have no idea how to go about that.

And a few more pictures of Lunenburg: