I don’t want to bother writing instructions for sewing fabric face masks – Leah Day’s instructions are the most comprehensive I’ve come across, although I made modifications as I went along.

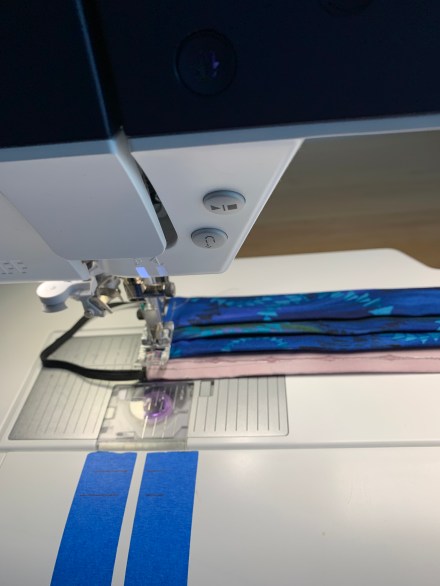

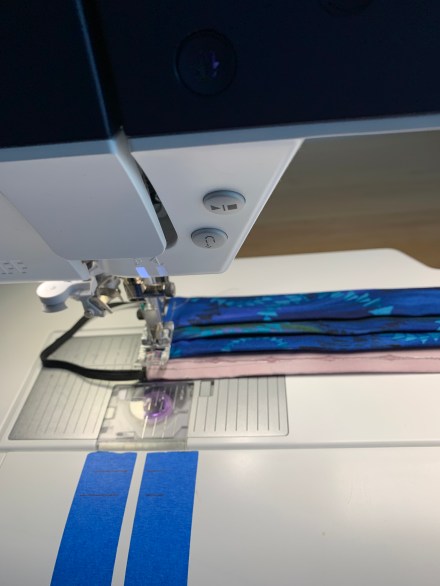

Sewing Side Seams – Elastic in Place

First of all, I had already cut a pile of fabric 6″ x 9″ (Leah cut hers 15″ x 9″ – I found that a bit too long from nose to chin) so instead of putting the cut pieces aside I sewed two together and treated them as a single piece (although shorter than 15″).

The part that may be hard to follow in Leah’s instructions is her step #5 – it’s a bit easier to see where the 1/2″ seam goes with what I’ve done – the seam is a bit more than 1/2″ above the fold (which is in the second fabric). In the picture above you can see that. You can also see as I sewed the 1/4″ side seams that the elastic is held in the corner with a quilting clip (I don’t use mine very often be they’re perfect for this project! Leah’s suggestion.)

Pipe Cleaner Clipped In Place

With the side seams sewn, turn the mask right side out, press flat. Next, I slipped a piece of pipe cleaner (I’ve also used twist ties) into the fold opposite from the opening (Leah put the pipe cleaner on the near side – I think the opening lays flatter with my adaptation leaving the opening at the bottom rather than the top of the mask). I used a clip to hold the pipe cleaner in place.

Stitching Pipe Cleaner In Place

With a 1/4″ quilting foot with centre guide, I stitched a 1/4″ seam across the entire top edge using the guide to hold the pipe cleaner against the fold – worked nicely.

Pipe Cleaner In Place

You can see the 1/4″ seam holding the pipe cleaner in place in the bottom of the picture.

Now, I had done the next step before inserting the pipe cleaner. Leah carefully measures where to pleat the mask – that’s fine if you’re doing one or two. I’m planning on 100 – too time consuming. I’d seen another video where the gal folded the mask in half, pressed, folded it into quarters, pressed. I’d recommend doing the folding/pressing AFTER inserting the pipe cleaner/twist tie/floral wire – whatever you’re using.

Pleats folded

Next it’s time to fold the pleats. I put the mask open side down, opening at the bottom, and began folding from the bottom toward the top, clipping the folds as I went along to hold them.

Sewing Pleats Down

I found it easier to sew the pleats with them facing me, the presser foot (I used the universal foot for this operation) flowed over the fold better, but that meant sewing one side of the mask with the bulk of the mask within the harp (usually the bulk of the sewing is to the left, outside the harp). The other side of the mask gets sewn in the usual way, since the pleats are going in the right direction. Also, I used a 2mm stitch to sew the pleats – just a bit more secure.

I didn’t bother edge stitching the whole face mask. Didn’t think it was required.

16 Completed Face Masks

One other thing – I cut my elastic 6 3/4″ in length which I found was long enough for my face. I recommend doing a test run to check the finished length from nose to chin, and width including elastic before going into any kind of production mode.

Why the opening in the bottom of the mask? Well, first of all, you need it to be able to turn the mask right side out after you’ve sewn the first seams. Leah left it open so that a surgical mask, (or some other breathable but less permeable material like a piece of vacuum cleaner bag) could be inserted inside, making the cotton face mask a cover rather than the mask itself.

I have 10 more masks set up to work on tomorrow (using my 6″ x 9″ pieces). When those are done, I plan on doing another couple of batches following Leah’s instructions – a single folded piece probably 13 1/2″ in length and follow on from there.